Radiasun is the leading manufacturer of cable and satellite meters in the world. Radiasun delivers the most satisfying products and services to the customers all over the world, with our own brands name, and also provides OEM and ODM for the most famous brands in the field.

AV6416-OTDR

AV6416 OTDR Cleaning Optical Devices - 28/26/24dB high dynamic range(1310nm/1550nm/1490nm)

Cleaning Optical Devices

Please Note:

Always clean optical connectors before using them.

Clean the fiber end before test.

Keep the instrument free of dust.

Regular cleaning of optical connectors will help maintain measurement accuracy.

Always cover connectors with protective caps when instrument is not in use. Be careful when replacing dust caps after use. DO not press the bottom of the cap onto the fiber too hard, as any dust in the cap can scratch or pollute your fiber surface.

It is important to clean optical devices:

In transmission links optical fiber cores are very small size in diameter. Dust and other particles, however, can range from tenths to hundredths of microns in diameter. Their comparative size means that they can cover a part of the enf of a fiber core, and as a result will reduce the performance of your system.

Furthermore, the power density may burn dust into the fiber and cause additional damage. If this happens, measurements become inaccurate and non -repeatable.

Please follow the following safety rules:

Make sure that you disable all sources when you are cleaning any optical interfaces.

Under no circumstances look into the end of an optical device attached to optical outputs when the device is operational. The laser radiation is not visible to the human eye, but it can seriously damage your eyesight.

Do not install parts or perform any unauthorized modification to optical devices.

Standard Cleaning Equipment

Isopropyl alcohol

Cotton swabs

Soft tissues

Compressed air

Isopropyl alcohol:

If you use isopropyl alcohol to clean your optical device, do not immediately dry the surface with compressed air (except when you are cleaning very sensitive optical devices). This is because the dust and the dirt is solved and will leave behind filmy deposits after the alcohol is evaporated. You should therefore first remove the alcohol and the dust with a soft tissue, and then use compressed air to blow away any remaining filaments.

Do not use any other solvents, as some may damage plastic materials and claddings. To avoid damage, only use isopropyl alcohol.

Cotton swabs:

Enusre that you use natural cotton swabs. Foam swabs will open leave behind filmy deposits after cleaning.

Use care when cleaning, and avoid pressing too hard onto your optical device with the swab. Too much pressure may scratch the surface, and could cause your device to become misaligned. It is advisable to rub rently over the surface using only a small circular movement.

Swabs should be used straight out of the packet, and never used twice. This is because dust and dirt in the atmosphere, or from a first cleaning, may collect on your swab and scratch the surface of your optical device.

Compressed air:

It is essential that your compressed air is free of dust, water and oil. Only use clean, dry air. If not, this can lead to filmy deposits or scratches on the surface of your connector. This will reduce the performance of your transimission system. When spraying compressed air, hold the can upright. If the can is held at a slant, propellant could escape and dirty your optical device. First spray into the air, as the initial stream of compressed air could contain some condensation or propellant. Such condensation leaves behind a filmy deposit.

To clean connectors :

Trun off power.

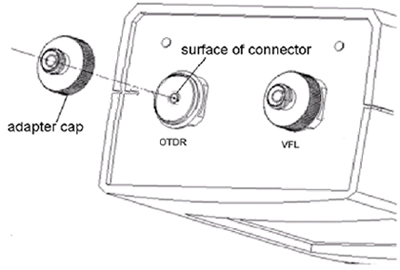

Remove the adapter cap from the outports of instrument to expose the connector baseplate and ferrule.

Clean the connectors by rubbing a new cotton-swab with isopropyl alcohol over the surface using a small circular movement.

Take a new, dry soft-tissue and remove the alcohol, dissolved sediment and dust, by rubbing gently over the surface using a small circual movement.

Blow away any remaining lint with compressed air.

Afer clean, put adapter cap back onto the connector.